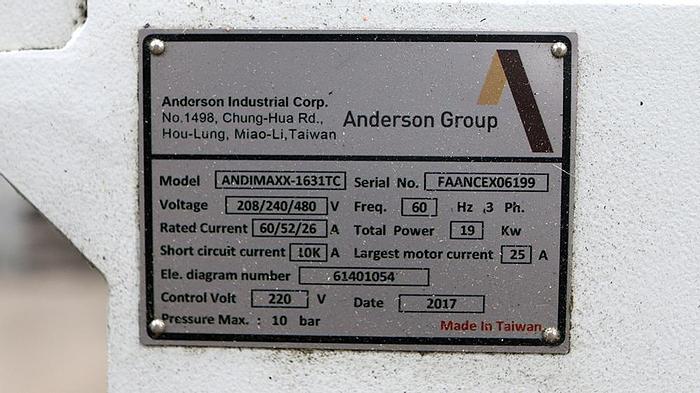

2017 Anderson ANDI ANDIMAXX-1631TC

2017 Anderson ANDI ANDIMAXX-1631TC

Location:Grand Rapids, MI

Description

Available for immediate delivery to take advantage of section 179... Located in Holland Michigan and available to see in operation via web meeting or in person. Please call James Scarlett to schedule a demo 616.308.9800

MACHINE FEATURES:

Fixed Bridge (moving table) type machine equipped with 1 (one) 18 HP 4-pole air-cooled router spindle, with grease lubricated ceramic bearings, DUAL 12-Position Automatic Tool Changing Systems, with tool length touch probe. The spindle motor is powered by an electronic AC inverter drive system with dynamic spindle braking. Full Torque is achieved at 9,000 RPM & Full HP is achieved at 12,000 RPM. The Automatic Tool Changer Carousel, with Steel Tool Holder Clips, is mounted on the spindle carriage, next to the Router Spindle, for fast & efficient tool changes. X & Y axes are constructed of massive, heavy duty welded steel construction with multiple reinforcements to increase strength and absorb vibration. Z-axis spindle carriage is a specially designed Meehanite casting for high strength and inherent vibration dampening characteristics with a pneumatic counterbalance system for smooth and accurate operation. Hardened & Precision GROUND Rectangular Boxway guide-ways, with recirculating roller bearings, are provided for all primary movements in the X & Y axes. Roller Boxways provide far more metal to metal contact than radius-contact ball guide systems for up to twice the load capacity, one third the elastic deformation, twice the static stiffness, up to 200% longer life, with significantly better dampening of tool induced vibrations. Hardened and precision STAR profiled linear guide way systems with recirculating roller linear bearings are provided for movements in the Z axes. Hardened and precision ground ball screws with anti-backlash ball nuts are provided for all primary movements of the X, Y, & Z axis.

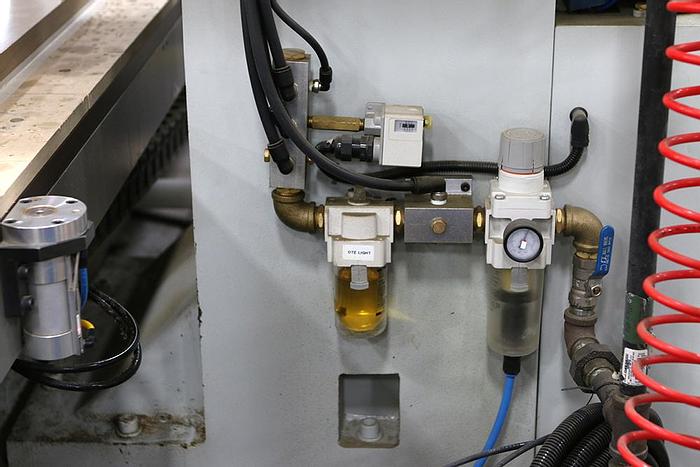

The vacuum table is made of torsion resistant cast steel, covered with a 30mm thick, phenolic grid table top for the quick and easy mounting of work pieces via pods, clamps, spoilboards, or holding fixtures. Eight (8) pneumatically controlled Popup pins are mounted around the table perimeter for Nested Based Manufacturing. The table is configured with one vacuum zone, which is m-code controlled. The vacuum zones are equipped with a low vacuum sensor. This table and pump combination will allow a wide range of flexibility in holding large & small work pieces. State-of-the-art closed loop FANUC AC digital servo motors are utilized on X, Y & Z axis. Automatic oil lubrication is utilized for box guide ways & ball screws. Centrally located grease fittings are utilized for end bearings and profiled linear guide ways. All guides are protected from dust and other contaminates by double sealed wipers. The operator control panel has a Handheld Pendant with separate Feed Rate & Rapid Rate Override. A dust collection hood with automatic damper system is provided for the router spindle.

CONTROL FEATURES: FANUC OiM-F Controller System + Windows PC Front End User Interface. Slots are optional (not included) for an additional 2GB of part program storage.

TECHNICAL SPECIFICATIONS: Table size 1600 mm x 3100 mm (63” x 122”) Pop-Up Positioning Pins 8 Vacuum Zones per Table 1 (one) Axis stroke X-axis: 2000 mm (79”) Y-axis: 3800 mm (149”) Z-axis: 250 mm (10”) Single Axis Rapid Rate X-axis: 80 meters/min (3,150”/min) Y-axis: 80 meters/min (3,150”/min) Z-axis: 30 meters/min (1,180”/min) Maximum Rapid Traverse All-axis: 113 meters/min (4,448”/min) Spindle #1 - Router Spindle Spindle type Anderson 4-Pole Grease Motor power 13.5Kw (S6): 11Kw (S1) Spindle speed (RPM) 1000-22000

No. of changeable tool slots= 24, Spindle taper= HSK63F, Aggregate Torque Ring INCLUDED

Machine footprint Floor area 142” x 319” Height 116” Net Machine Weight 13,650 Kg* (30,100 lbs.) *not including pump(s)

Specifications

| Manufacturer | Anderson |

| Model | ANDI ANDIMAXX-1631TC |

| Year | 2017 |

| Condition | Used |