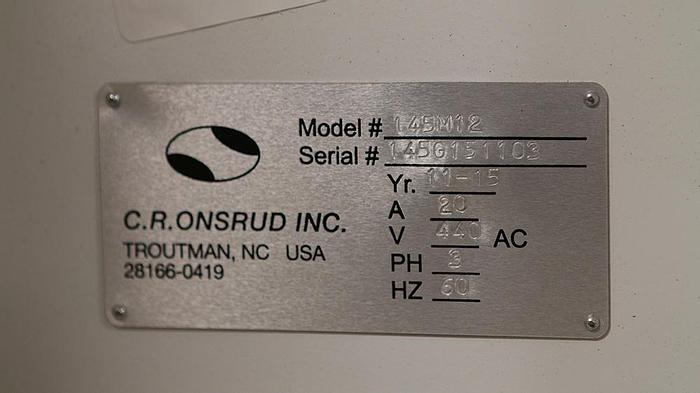

2015 C.R. ONSRUD 145M12

2015 C.R. ONSRUD 145M12

Location:Grand Rapids, MI

Description

Designed, FEA Engineered, and Manufactured in America, utilizing steel construction.

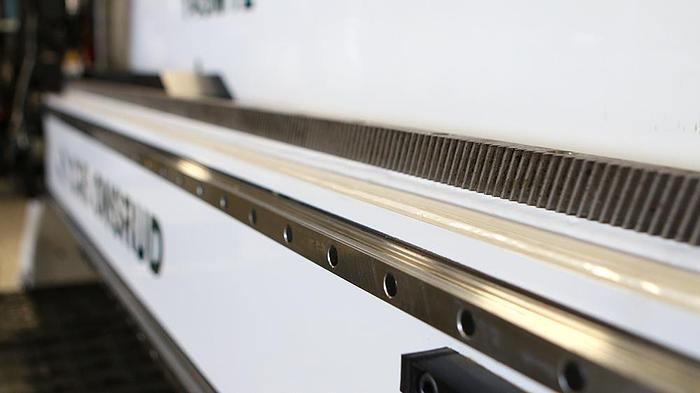

Dual supported gantry driven on both sides with independent servo motors and drives. This dual-channel design enhances accuracy & rigidity.

The moving gantry, fixed table, the design allows for up to 2,000 ipm programmable feed rates.

The Control system comes standard with full 3D capability (multi-axis interpolation).

Precision linear motion systems on all axes.

Standard with Onsrud Universal High Flow Vacuum Table System suitable for flow-through spoil boards, dedicated fixtures, or easily upgradable for pod systems.

This machine is physically located at Scarlett Inc’s showroom in Grand Rapids MI. Please call to arrange a visit, we are 3.5 minutes from the airport and would be happy to pick you up. Please note that the below description is from the original manufacture spec. For a more detailed description please call James to discuss if this machine will fit your needs. 616.308.9800

CR ONSRUD High-Flow Universal Vacuum Table System - Includes: oversized 4” intake manifold, high-capacity vacuum plumbing, high-flow 45mm grid waffle patterns, with Onsrud’s Unique High Flow Vacuum Inlets, to offer maximum vacuum airflow & absolutely minimal airflow restriction for excellent part holding.

High Flow Vacuum Zone - Pneumatic Ball Valve, Actuated via Push Button or PLC Controlled

9-inches of Z stroke - 10” under bridge clearance & 9” Z axis stroke.

5x12 - Flow-Through Spoil Board - LDF table top to be used as replaceable sacrificial spoil board.

OSAI Top 5 Controller System with Handheld HMI - OSAI Top 5 control comes with touch screen handheld HMI, network capability, Industrial CNC Motion Controller, plus adds OSAI Digital Drives, Amps, and Servos (requires 460V out isolation transformer)

12 HP Spindle - 4-Pole, 9Kw, 12HP, HSK-63F – 24,000 RPM fully programmable, variable speed, reversible, quick-change cartridge style spindle, with air blast; capable of routing & drilling, with programmable feed rates with override capability.

Integrated Dust Transition System - Integrated Dust Extraction hood pulls chips away from the spindle’s nose & up a separate chamber & hood to effectively remove chips from the machining process. (6in dust transition also provided for connecting to your dropped-in flex hose) - **consult your machine-specific footprint for specific connection recommendations based on your options.

Standard Manual Greased Lubrication - Bearing Blocks and Ballscrews have standard zirk fittings for easy application of grease

Dust Collection Side Stanchion Kit - (includes flex hose, 2 steel stands, & clamps to connect the provided dust transition to your collector, above to the left, or above to the right of your moving gantry machine’s footprint)

10 Tool – Hide Away Rack Tool Changer - Allows the Entire Rack tool changer Assembly to retract beneath the tables surface & adds a retracting cover to help protect tooling from dust &/or debris. This upgrade also increases compatibility with material handling, loading, & offloading systems. Able to Store Aggregates. You may not be able to hold some larger or non-standard aggregates

Air Conditioned Electronics Cabinets - Recommended for extreme environments & some non-temperature controlled workplaces. Option replaces the standard heat exchanger system.

Specifications

| Manufacturer | C.R. ONSRUD |

| Model | 145M12 |

| Year | 2015 |

| Condition | Used |