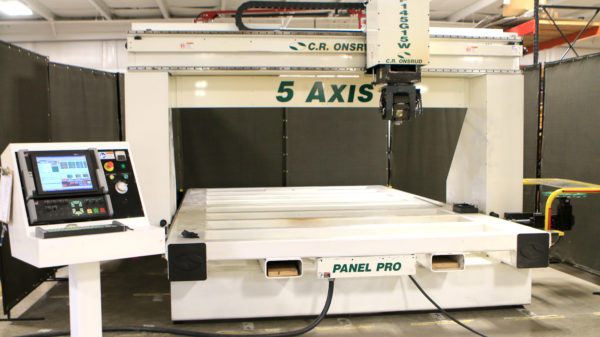

C.R ONSRUD MODEL F145G15W10 “5-Axis Pro Series” CNC ROUTER

with: Thermal Heat Treated, Stress Relieved, & Normalized, Two-Piece Steel Frame Base, & Thermal Heat Treated, Stress Relieved, & Normalized Steel Bridge; Dual Support, Dual Drive, Moving Gantry, Fixed Table Design with standard 2,000” per minute machining speed, full 3-D capability, precision ball screw drives for Z & Y axis, case-hardened, precision ground, helical rack & pinion drives for X-axis, precision linear profile guide ways, centralized manual lubrication system. SINGLE FIXED TABLE, w/independently controlled vacuum zones & full table coverage.

Each zone has low vacuum sensing safety shut-off with override capability. Includes all switches, valves, gauges, safety interlocks, & Vacuum Plumbing necessary for either suck through or dedicated spoil boards, & is easily modified for the use of pod systems. Moving gantry has a pressure sensitive safety-stop / emergency-stop bar.

41-inches of Z stroke – Increases 5-Axis Frame under bridge clearance & Z-stroke 41 inches

FANUC 31i-B5 Machine Controller System Option With Integrated PC Interface – Industrial CNC Machine Controller with Fanuc Panel-i HMI w/High Res touch screen. Fanuc 31i-B5 is not a PC with a control card but is a dedicated Industrial PLC designed to control CNC motion, for maximum reliability and performance. Includes: Network capability, adds Larger FANUC Digital Drives & Servos. Includes Full remote diagnostic troubleshooting capabilities. Adds m-code controlled vacuum zones (if equipped with Vacuum Table Option). Provided with 4-port network hub (requires 460V out isolation transformer). Selecting this option replaces any other standard control system.

5-Axis 15 HP Short-nose Spindle – 4-Pole, 15HP – 24,000 RPM Double-Armature 5-Axis Spindle w/HSK-F63 Spindle Taper. Fully programmable, variable speed, quick-change spindle, capable of routing & drilling, programmable feed rates with override capability. A-Axis Rotation +/- 120 degrees, C-Axis Rotation + 300 / – 115 degrees.Chiller for Liquid Cooled Spindle Option – Adds a liquid cooling system & chiller in place of the standard fan & compressed air spindle cooling system. (Recommended when machining mostly non-ferrous metals or when using 20HP spindles or larger)

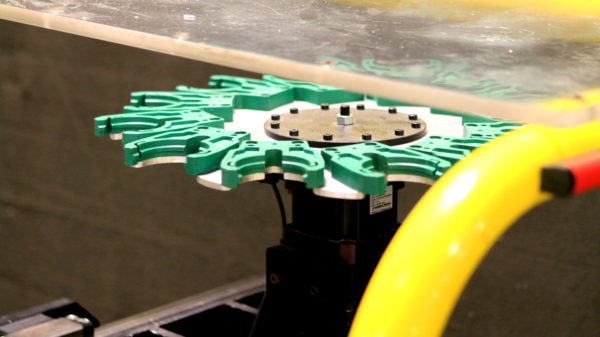

12 Tool – Dynamic Automatic Rotary Tool Changer – Fully Servo controlled instead of Stepper controlled or Rack-Style tool changers. The design eliminates misfires & quickly changes between 12 different tools – Able to Store Aggregates. You may require C-Axis or separate Aggregate Tool Changer option to hold some larger or non-standard aggregates.

Air Conditioned Electronics Cabinets – Recommended for extreme environments & some non-temperature controlled workplaces. Option replaces the standard heat exchanger system.

REPLACEMENT COST $372,348.00

SALE PRICE $149,000.00

Contact Scarlett for more Info:

sales@scarlettinc.com

616-871-9889