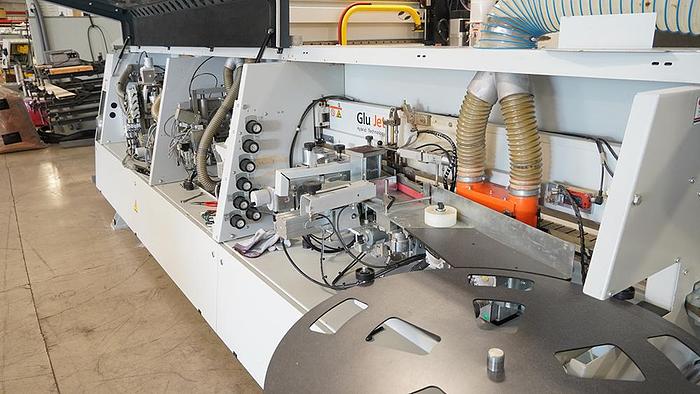

2016 Holzher Sprint 1329

2016 Holzher Sprint 1329

Location:Grand Rapids, MI

Description

A very well kept machine in Good condition. Currently located in Grand Rapids MI Scarlett Inc showroom, please call for demonstration

The 1329 is the fully servo-controlled machine you've been looking for.

This 2016 Holzher 1329 Edgebander has approximately 1480 hours on it and has processed 183,000 pieces or 104,000 linear meters of material.

Please call James Scarlett at 616.308.9800 for more information.

Machine Layout

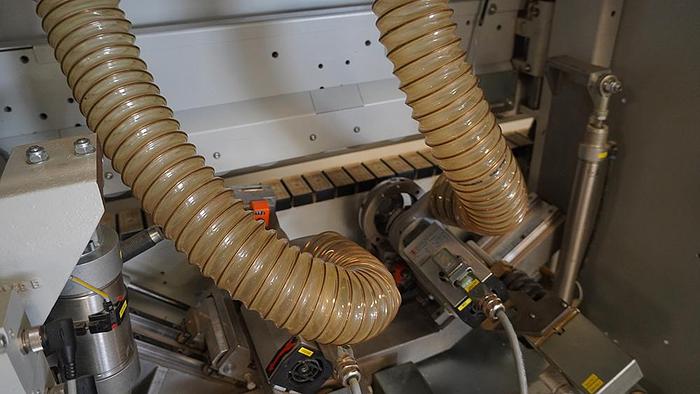

Pre Milling Station (1802)

To pre-mill workpiece in advance of edgeband application.

To provide a razor-sharp, clean, straight edge and ensure the best possible glue line.

With 2 cutter units, (1) counter clockwise and (1) clockwise rotation

Motor power: 2 x 2 kW. 200Hz.

Servo controlled infeed fence

Maximum stock removal: 3 mm

Patented ProLock clamping system for rapid tool changes

Include 2 diamond cutters Ø 70 x 64 x 30 mm.

CM technology with integrated dust removal (LEUCO system)

Max. workpiece thickness 60 mm

EDGEFEED MAGAZINE (1901 SYNCRO)

Fully automatic feed of coils and strip material.

Edge banding thickness 0,3 – 12 mm

Utilizes motion detector to ensure accurate, trouble-free positioning of edge material.

Exclusive “TRACTOR-BELT FEED SYSTEM” to ensure accurate feeding of edge material, as well as optimum operator safety.

Magazine table on rollers for smooth feeding of coiled material.

“NARROW APPROACH ANGLE” allows easy feeding of large wood edges. Exclusive only to HOLZ-HER Edgebanders

Automatic guillotine for coiled material up to 3.0 mm.

GLUING STATION - GluJet hybrid technology (GJ-301)

Glue application through a nozzle applicator

Automatic reload of the glue cartridges or granulated pellets.

For glue cartridges and all commercial granulated hotmelts

Workpiece thickness 6 - 60 mm (Depending on feed speed and glue viscosity)

Heat-up time approx. 3 min.

Feed max. 18 m/min

Workpiece length min. 140 mm

Pressure controller for regulating the pressure at which the adhesive is applied

Automatic glue temperature reduction according to time

Automatic rinse function directly from control panel

Magazine capacity:

Cartridges: 4 cartridges (approx. 1,4 kgs)

Granulated glue: approx. 1,5 kgs

Tracing nozzle

The tracing nozzle allows compensation for variances in the panel thickness.

The sensing shoe is spring loaded and opens the nozzle exactly to the precise panel thickness.

This ensures perfect, clean glue application even on panels with high thickness variances

ADAPTIVE PRESSURE AND GLUE QUANTITY CONTROL

Automatic, program controlled fine adjustment for edge thickness, edge materials, and glue types – guarantees best possible results

Automatic glue quantity control (based on edge material and glue type)

Automatic adaptive guillotine (based on edgeband thickness)

Automatic pressure section (based on edge thickness and type)

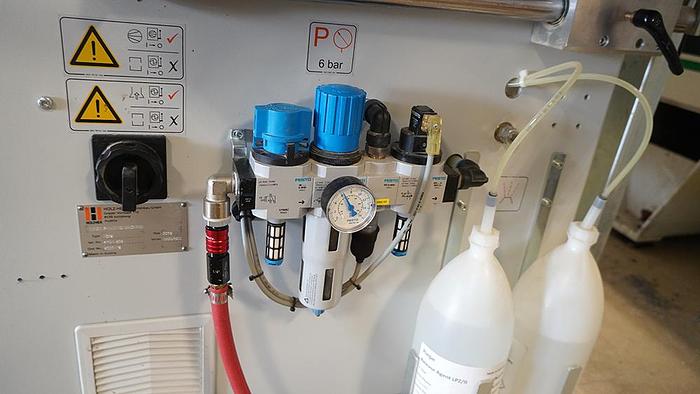

SPRAY SYSTEMS:

For the in- and outfeed area (1856)

Useful when using PUR glue

Infeed area: electronically controlled release agent sprayer

Outfeed area: electronically controlled cleaning agent sprayer

MOTORIZED PRESSURE UNIT (1913-M)

With 1 axis servo motor for the adjustment of the edge thickness. Fully automatic plunge control of all pressure wheels.

For edgeband up to 12 mm.

With individually controlled pneumatic pressure system for each roller.

One of the rolls is cylindrical and two are slightly conical.

END TRIM UNIT (1918- P)

Heavy duty design with linear guide bars for precision end trimming.

Two high frequency motors for cutting the leading and trailing edges with draw cuts.

Mounted with uni-point axis enabling quick change to chamfer trimming up to 10°.

Mechanically indexes to workpiece ends for a perfect finish.

Motors:(2).45 kW, 9,000 RPM.

“PCS” Pneumatic Changeover System included as standard

Two (2) TCT carbide blades included.

Edgebanding thickness: max. 12 mm.

HIGH FREQUENCY TOP/BOTTOM TRIMMING UNIT (1826MOT6)

For high production top & bottom trimming of all edge materials

Edge Thickness Capacity = 3 mm radius and 8 mm flush cutting, depending on tooling.

Pro-Lock screw in spanner for quick tool changes.

Motors 2 x .65 kW, 200 HZ

Cutterhead Speed: 12,000 RPM.

Bevel Capability: 0 - 45º (depending on tooling).

Integrated vertical and horizontal copy wheels.

Uses multi-purpose diamond tipped heads for flush, bevel, or radius trimming.

(6) SERVO MOTOR ADJUSTMENTS

SHAPING TRIMMING UNIT (1833 MOT 4)

For top/bottom trimming and rounding of corners: radius, chamfer.

Can be programmed for use as a second top/bottom trim unit.

Unique programming enables a complete and consistent radius on all edges of the workpiece

Rapid tool changes via patented ProLock quick-change system

Two motors, 2 x 0.4 kW, 200 HZ.

(4) servo motors for quick programmable adjustments

Equipped with 3mm radius diamond cutterheads (stock from factory, cutterheads may be different on current model)

Feed speeds during shaping cutting:

workpiece thickness up to 25 mm = feed up to 18 m/min

workpiece thickness up to 38 mm = feed up to 16 m/min

workpiece thickness up to 60 mm = feed up to 12 m/min

PROFILE SCRAPER UNIT (1929-MOT4)

Uses reversible insert carbide scraping knives on the top and bottom edges.

Equipped with 3mm radius tooling to finish and remove knife marks created by the top, bottom, and radius units on thick PVC edgings.

Vertical and horizontal copy wheels

Motorized adjustment of the horizontal copy wheels (4) servos

FINISH SCRAPER (1964)

Flat knives scraping along board/banding joint

Pneumatic engage/disengage via controller

Plunge-in controlled top and bottom separately

Includes: 2 blow nozzles, 2 insert knives

BUFFING UNIT (1940)

Includes 2 x 0.09 kW. motors.

Vertical Tilt = 0 to 5 degrees.

Cloth buffing wheels for smoothing the sharp edges of thin PVC band after trimming.

Motor Speed = 1440 RPM.

TECHNICAL DATA:

Machine Dimensions:

Length: 5023 mm / 197.75 in.

Width: 934 mm / 36 in.

Height: 1388 mm / 54 in.

Working Dimensions:

A - Workpiece Thickness: 6 - 60mm / .23 – 2.36 in.

B - Edging Thickness: 0.4 – 8 mm / .02 - .31 in.

B - Edging Thickness (Optional Flush Cutters): 0.4 – 12 mm / .02 - . 47 in.

C - Edging Width: 65 mm / 2.56 in

D - Edging Overhang 2.5 mm /.118 in.

E - Workpiece Width: Min. 65 mm / 2.56 in

F - Workpiece Length: Min. 160 mm / 6.29 in.

Edging Strip Length (laminate strips, etc.) Min. 350 mm (13.78 in) - Unlimited

Feed Speed: Variable 10-18 mpm / 32.8- 59.1 fpm

Air Requirement: 6 bar

Specifications

| Manufacturer | Holzher |

| Model | Sprint 1329 |

| Year | 2016 |

| Condition | Used |

| Edgebanding thickness | max. 12 mm. |

| Maximum stock removal | 3 mm |

| Air Requirement | 6 bar |