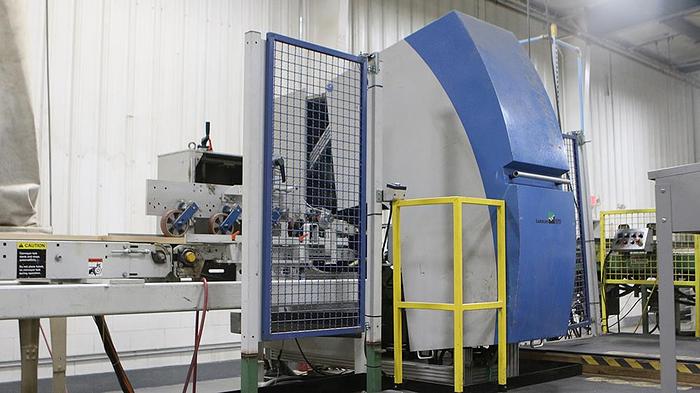

Weinig Scanner and Chopsaw System

Weinig Scanner and Chopsaw System

Location:Grand Rapids, MI

Description

This is a whole system for sale that includes a scanner and a chop saw. There is a lot of detail on this one. please inquire for more information.

Weinig Opticut 200 and a Weinig Luxscan Scanner.

Opticut 200 Elite Description

Saw aggregate

Sawblade diameter

TCT-sawblade, Z (tooth)=144, alternating tooth 20°

Sawblade bore

Speed of sawblade max.

Ingoing lengths min./max.

Ingoing widths for removal of waste via blowing

out (standard) min./max.

Ingoing widths for removal of waste via waste

pit (optional) respect. at belt end min./max.

Ingoing thicknesses min./max.

Cross sections generally rectangular

Nominal cross sections (without board bend)

max.

max.

max.

Ø 500 mm

30 mm

3600 rpm

400 - 4895 mm

30 - 200 mm

30 - 260 mm

12 - 80 mm

200 x 60 mm

260 x 12 mm

160 x 80 mm

365253*

Fixed length at rear of saw

with waste removal at the belt end

with waste removal via blow-off device in the saw

with fixed waste pit

with automatic waste pit

Bend of the boards in all directions

Thickness tolerance

Cutting tolerance

(at a timber quality with a minimum share of resin

and a plane surface

min. tolerance for fixed lengths up to 1 m

max. tolerance for longer parts up to 2.5 m)

Timber species: Soft-/Hardwood

min. 140 mm

min. 140 mm

min. 400 mm

min. 140 mm

max. 10 mm / m

+/- 3 mm

+/- 0.8 – 1.5 mm

963243*

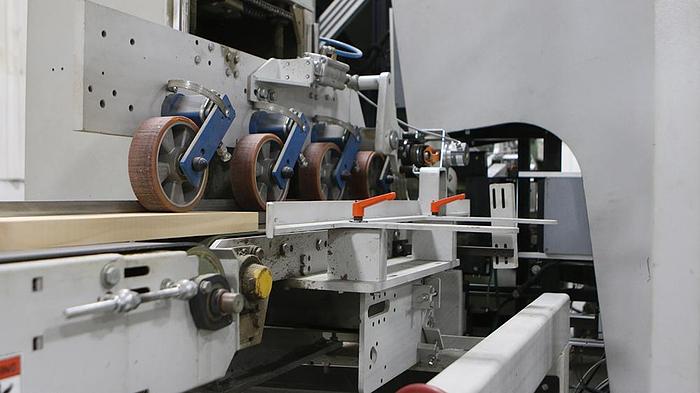

Feed speed infinitely variable

Time per cutting operation including

slow-down, cutting, acceleration

In order to obtain the real production figures the capacity has to be multiplied with an efficiency factor corresponding to client's production requirements.

max. 250 m/min.

0.7 - 1.2 sec.

Motor power saw

Motor power feed system

7.5 kW (10 HP)

3.0 kW (4 HP)

Working height

Working height

1397 mm

Conveyor belt to cross-cut saw with Variospeed,

which is driven by servo motor independently from saw for minimization of the gap between 2 subsequent boards, maximum range of optimization 3800 mm.

Advantage:

Capacity increase of up to 20%, in comparison to conventional saw systems.

The dead times in the machine are minimized. The machine is considerably relieved by the independent arrangement of the infeed belt which enables higher acceleration and increased longevity of the motors.

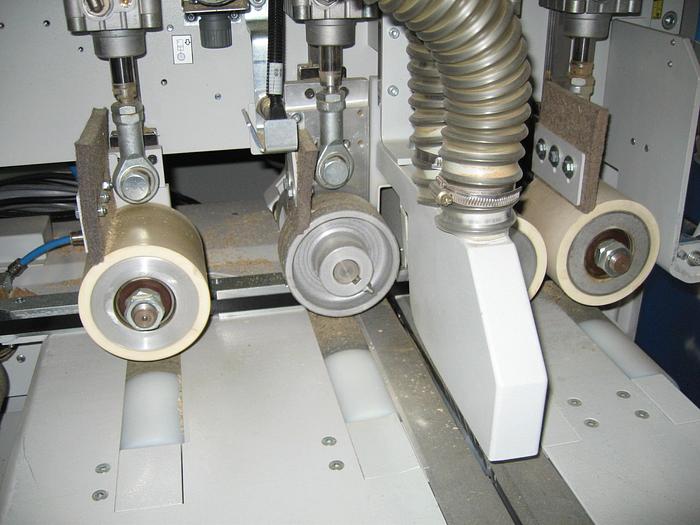

Outfeed / sorting

Integrated waste gate for sorting belt width 250 mm

Electro-pneumatically actuated, for a secure sorting out of waste pieces, directly at rear of saw, non-driven, in connection with sorting station

Max. waste length approx. 200 mm

Advantage:

A considerably increased performance by avoiding additional cuts in waste pieces. Longer endurance of the tools, lower air consumption. The patented waste gap enables a reliable discharge of waste pieces even before the sorting station without loss of capacity. Disturbances in the sorting process due to seized splitters etc. are impossible, direct linkages with the subsequent production units (moulding or finger jointing machine etc.) are made possible.

659009+

Outfeed conveyor belt / sorting station

with energy-efficient drive motor (energy efficiency class IE2),

without ejectors,

belt width 250 mm

Width of workpiece <= 300 mm

Belt length 31.5 ft

Variable speed of outfeed conveyor belt by means of motor with frequency converter

34399

SIX (6) Ejectors with squeeze protection

To be built-on outfeed conveyor belt (sorting station), max. weight of particular lengths < 20 kgs

Control

Operating device OptiCom Direct

with large TFT color display 12‘‘ and touch screen operation.

Technical data: 500 product groups storable (16 simultaneously for width measuring), 350 fixed lengths per product group, 50 ranges for variable lengths anyway spread over 8 grades, extensive production statistics.

Attention: Data import / -export in ASCII format, direct connection possible of a network-capable printer (statistics, data import/-export and printing only possible with package network connection).

Advantage:

Simplest operation in all languages! The control can be completely integrated in the company network. The production data can be retrieved in real time via the network.

Optimizing cross-cut saw OptiCut 200 Elite

Specifications

| Manufacturer | Weinig |

| Model | Scanner and Chopsaw System |

| Condition | Used |