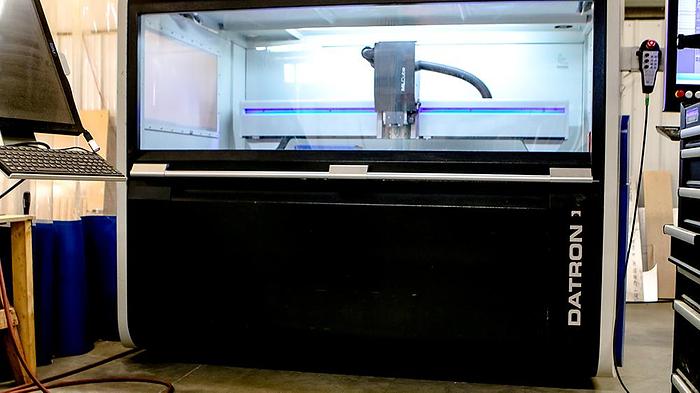

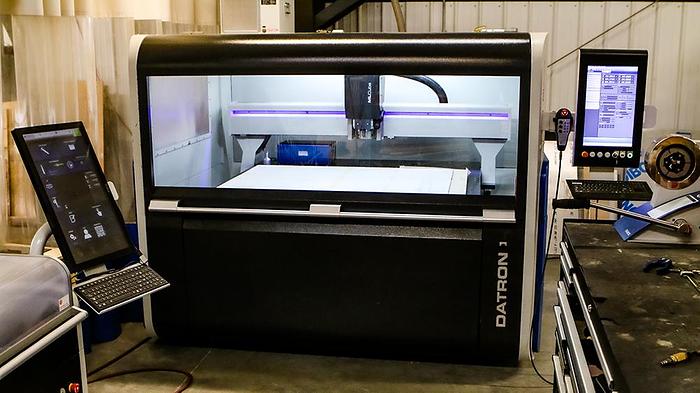

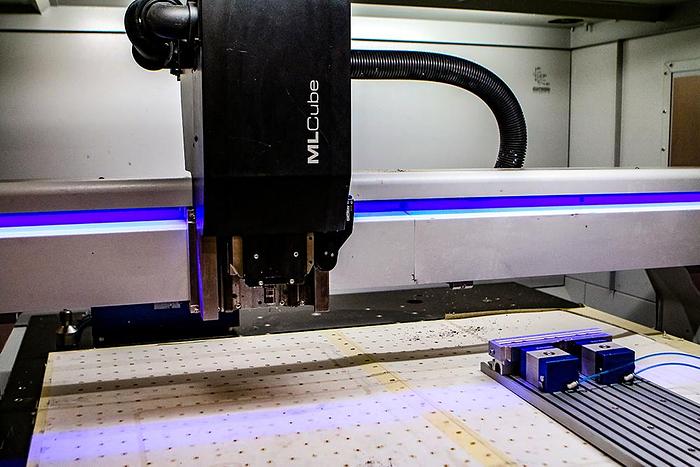

2017 Datron ML CUBE B

2017 Datron ML CUBE B

$1 (USD)

Location:Grand Rapids, MI

Description

Please call for pricing

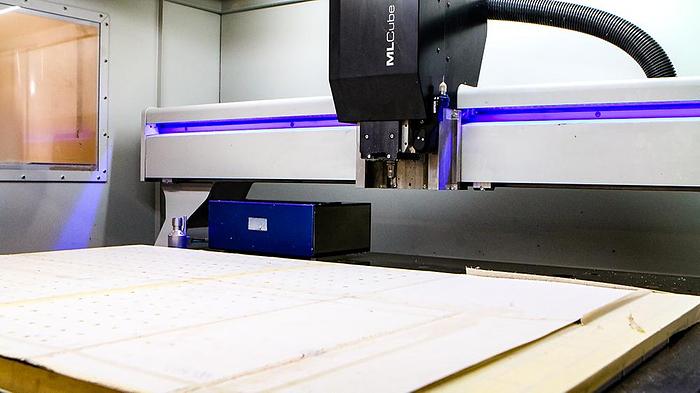

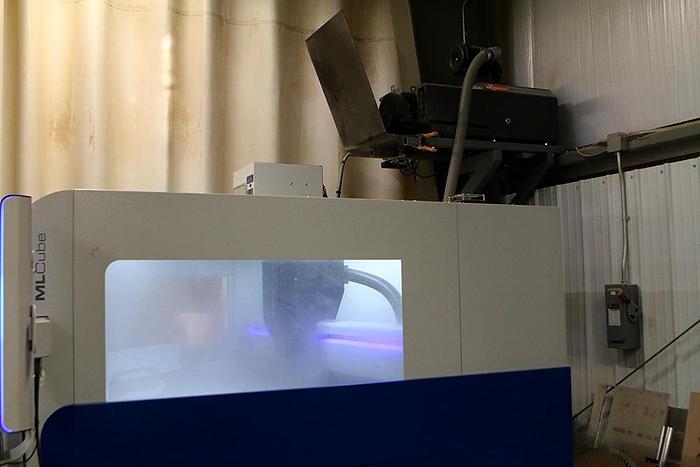

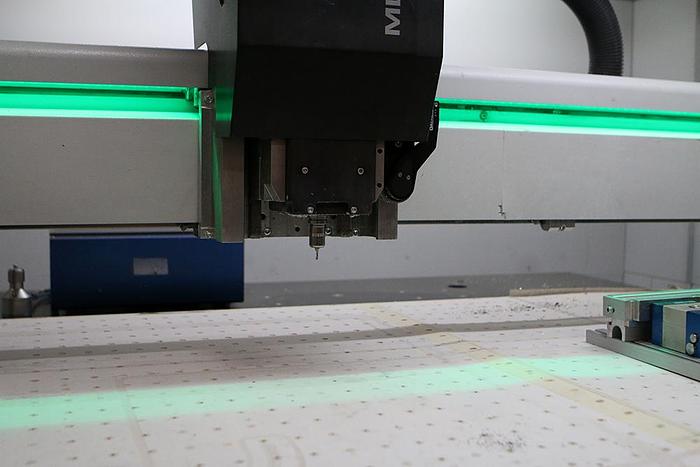

The DATRON MLCube is the best choice for cost-effective sheet machining, for example, for the production of front panels, housings, profiles and other aluminium workpieces milled in nested form. Other non-ferrous metals or composite materials can also be processed most efficiently with the MLCube. Its short setup times and its ability to use different clamping techniques simultaneously, its very low power consumption and its excellent price-performance ratio – even for low production volumes – provide long-term and extremely high profitability.

Benefits

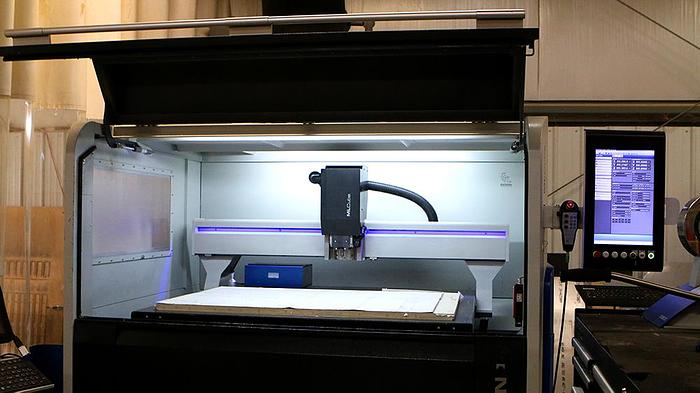

- Extremely large working area requiring little floor space.

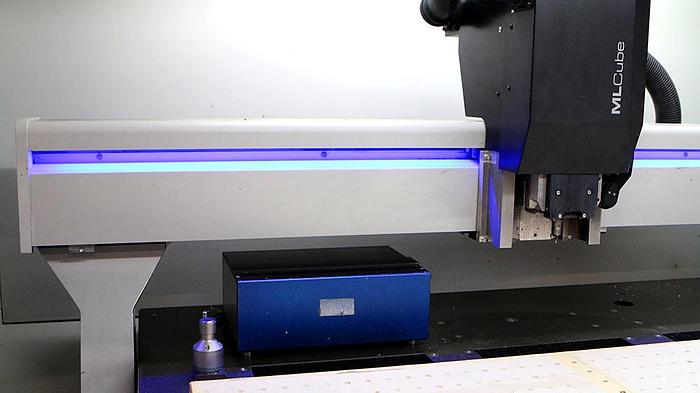

- New vacuum clamping technology with the possibility of electrically enabling/disabling different segments.

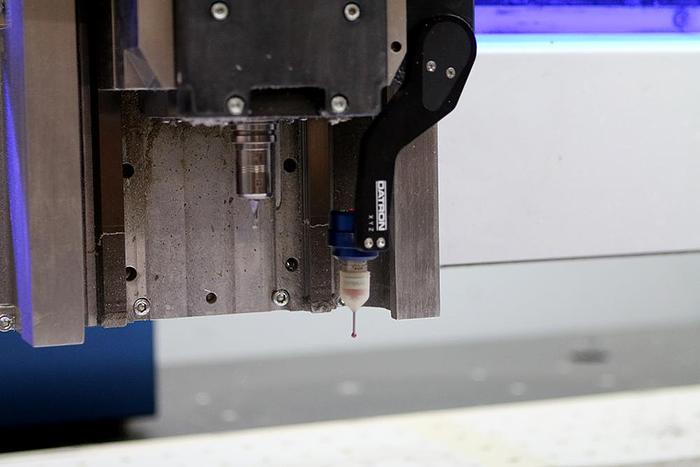

- Available with table cutout for vertical clamping technology, appropriate for machining high components (optional).

- Contour smoothing package PerfectCut for fast, accurate and contour faithful HSC milling with excellent surface quality: your machine is more powerful and stays “fit” longer, even in cases of high-volume production (optional).

- New chip carriage design with allocation to multiple containers (stackable) to promote work ergonomics.

HSCPro gives you maximum machine performance

HSCPro – Easy to use:

■ easy to learn intuitive menu navigation

■ fast operation by means of DATRON shortcuts

■ simple programming of powerful macro commands Numerous functions:

■ many milling cycles come pre-configured (e.g. pockets, holes, threads, conical countersinks)

■ continuous expansion through application-specific macros possible

■ protected areas as collision protection for clamping devices

■ different measurement cycles to calibrate the workpiece (including partial measurement field)

■ programme-controlled vacuum technology

■ PerfectCut contour smoothing filter

Maximum compatibility:

■ interfaces with all common CAD/CAM systems

■ Import of DIN/ISO programming codes (DIW 66025)

■ Import of HPGL, drilling data and CL-Print

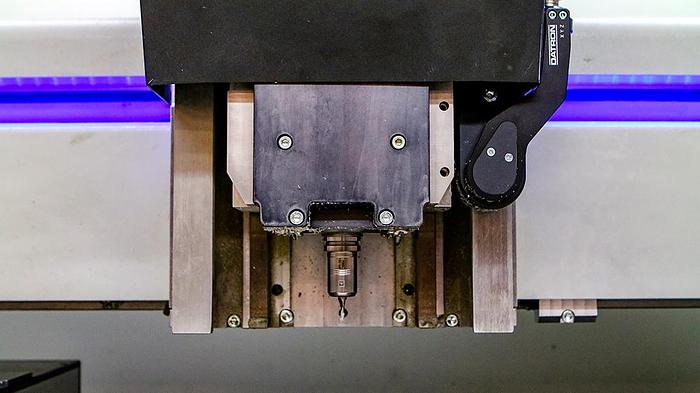

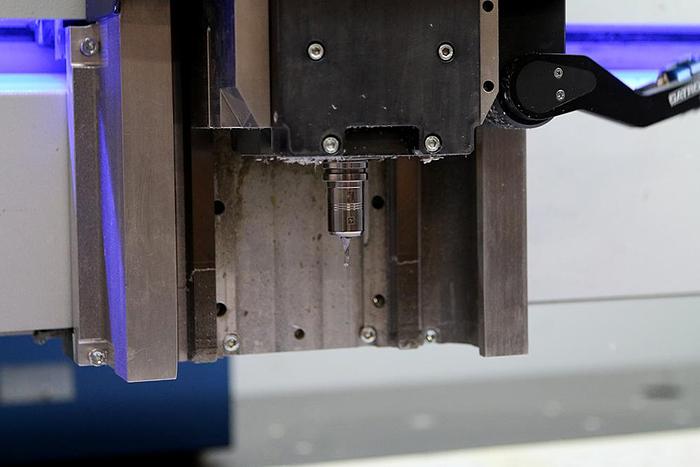

You can mill even the smallest free-form surfaces and complex geometries and get perfect results

■ Very high surface quality with all materials

■ Fast processing with very short segment lengths

■ Finest NC blocks with maximum feed rates

Cost-effective production by clamping within seconds: Setup times can be often reduced significantly with DATRON’s modular clamping technology. The module plates are clamped directly onto the machine table using conical centring sleeves. This applies to all machines with integrated cone clamping systems and allows very fast changing of clamping modules.

Specifications

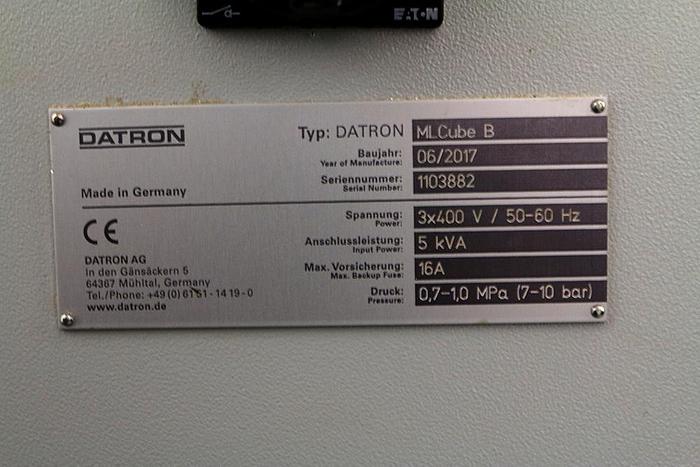

| Manufacturer | Datron |

| Model | ML CUBE B |

| Year | 2017 |

| Condition | Used |