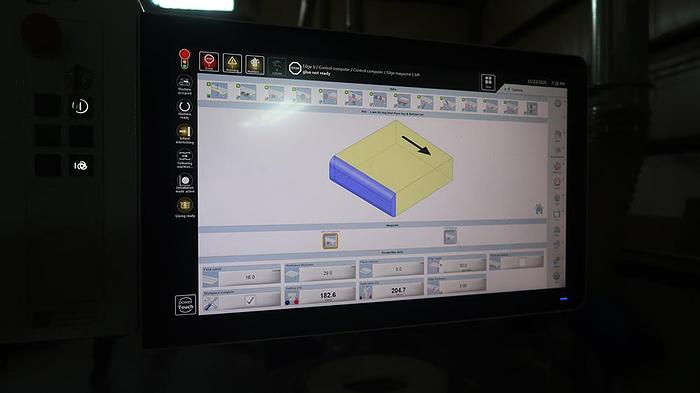

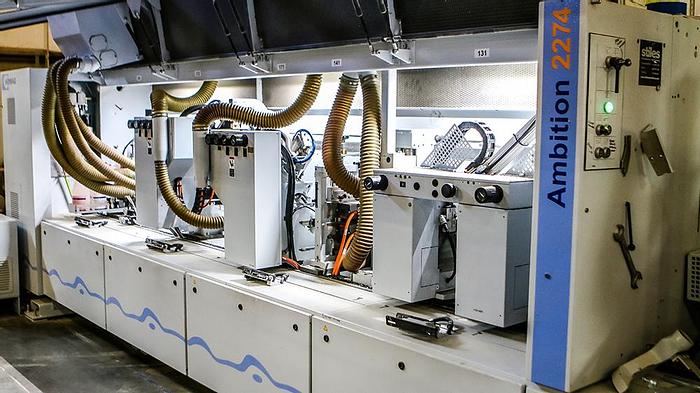

2015 Homag KAL370 Ambition 2274

2015 Homag KAL370 Ambition 2274

$53,000 (USD)

Location:Grand Rapids, MI

Description

The KAL 370 profiLine series is universally suited for any application, with feed rates of 20, 25 and 30 m/min. Select the right units for you from our extensive modular range. Workpiece infeed systems enable efficient, precise infeed of your workpieces.

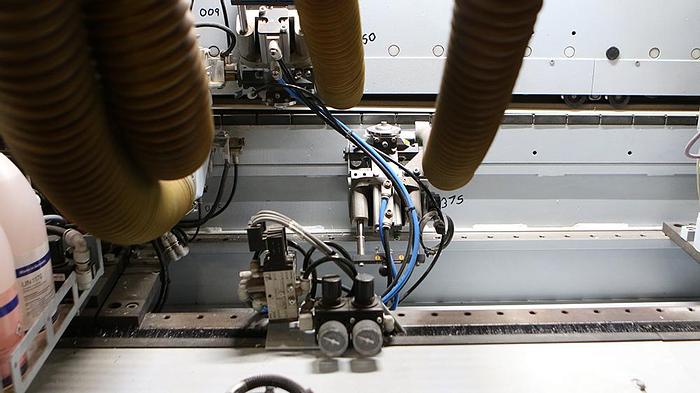

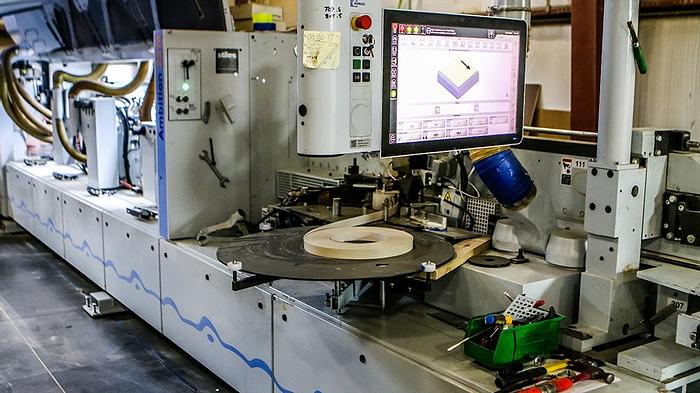

I-system – controlled chip capture

The chips are extracted already in the interior and selectively directed to the dust hood. Greater economy and a longer service life due to reduced wear and lower service costs. Reduced extraction speed drives down energy consumption and costs.

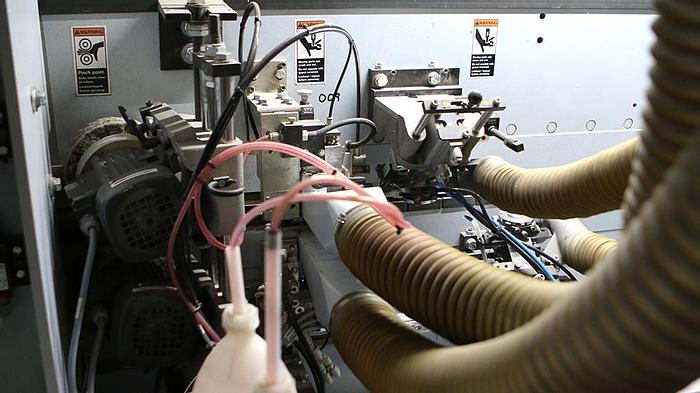

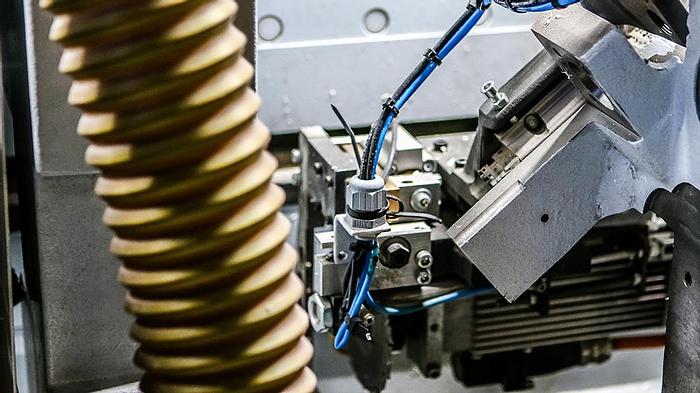

HSK interface

The hollow shaft taper (HSK) tool interface ensures a positive locking connection between the tool and motor shaft. Zero tolerances between the motor shaft and tool. This generates optimum trimming quality due to vibration-free tool concentricity.

The machines of the KAL 370 profiLine series process every workpiece completely. To ensure that the optimum solution is always available for your specific assignment, you can chose your own specific equipment configuration with this series, from the first work step through to the perfect finish. To ensure that every production step produces top-quality results, all the components are designed for perfect interaction. We recommend also asking about flexTrim and flexBlade, the 2-profile technology for fast automatic profile change.

The separating agent spraying unit and the jointing trimming unit ensure optimum preparation of your workpieces for gluing. The sprayed separating agent application simplifies the removal of glue residues. The jointing trimming unit provides the perfect basis for splinter-free glue joints with a consistently high standard of product quality.

HOMAG gluing units are the professional solution for fast, friction-locked glue joints. An EVA pre-melt unit comes as standard. The heated glue roller ensures an optimum glue temperature for all workpiece thicknesses and consistently high gluing quality. The magazine height adjustment permits different workpiece thicknesses to be processed with one edge height. If required, the gluing unit can also be equipped for you with a PU pre-melt unit – to enable rapid changeover to a different glue color or to PU.

Machine Specifications

machine length: 8,365 mm (27 1/2 ft)

working height: 950 mm (37 in)

extendable workpiece support: 800 mm (31 in)

variable feed speed: 16 – 20 m/min (52 1/2 – 65 1/2 ft/min)

workpiece overhang: 30 mm (1 1/8 in) operating voltage: 480 V

control voltage: 24 V

Your benefits at a glance

- Optimum glue application on the narrow surface

- Changes to workpiece thicknesses do not necessitate resetting of the glue application roller

- Magazine with 2 rollers for the fast, manual changeover of edges with single edge feed

- Glue roller lift-off on feed stop

- Easy-access granulate tank and level control

- Pre-melter for melting hot-melt glue as required either manually or automatically

- Sensor for glue level control in the application unit

• Glue roller with integrated heating guarantees constant temperature and viscosity for all workpiece thicknesses

• Electropneumatic glue roller and tank clamping prevents glue soiling on the trailing edge of the workpiece

• Individual drive for glue roller and first pressure roller synchronized with feed

• Tracing pad prevents wear of the application roller and ensures a consistent glue film thickness

• Simple removal of the application unit with quick-release lock

• Easy access to all functions from the front simplifies operation and maintenance

• Sensor for edge monitoring prevents hot-melt glue application on the workpiece where there is no edge present. This prevents contamination of the pressure rollers

• Manual height adjustment of the magazine

• airTec can be retrofitted

• Facility for mounting laserTec

For patent-related reasons this may only be used in Germany with Rehau edges.

Premium quality edge banding: Zero joint technology has fundamentally transformed furniture manufacture. The optical “zero joint” is the new quality standard for edge processing in the furniture and interior fittings trade. Using both the airTec and the laserTec method from HOMAG, you can produce furniture with an unprecedented standard of edging quality.

Specifications

| Manufacturer | Homag |

| Model | KAL370 Ambition 2274 |

| Year | 2015 |

| Condition | Used |

| Stock Number | D-1549 |